San Antonio Residents - Learn Lean Six Sigma’s History Here

Contact Us

As Lean Six Sigma has become a broad term over the years and more organizations are trying to implement it along with students and professionals wanting to learn it, we consider at Lean Six Sigma Curriculum for San Antonio High School Students of Texas that learning where it came from and its origins overall is a great way to start and understand, in-depth, why you should learn it today.

Let’s establish the fact that Lean Six Sigma is a combination of Japanese management processes and its principles that can be later traced back to the United States. The Japanese influence in the method comes from the Kaizen methodology that focuses on continuous improvement by relying on cooperation and commitment.

Unlike other methodologies, the Kaizen one bases part of its principles around the idea that every small and positive change is what can bring the most improvements while also eliminating all unnecessary processes or steps, saving more time in the process.

This Japanese methodology was implemented by dozens of companies in Japan and established them as great competitors for the products, ideas, and services obtained.

Now, it can be traced back to the USA as a new methodology to answer and compete with the Japanese industries was needed. This is how LSS was established in the 1980s to compete with Japan’s superior products and adopt Japanese principles to obtain better results.

These principles focused on reducing waste through non-value-adding actions and were adopted by many large U.S. companies in the 1990s.

Lean & Six Sigma: How LSS Truly Started

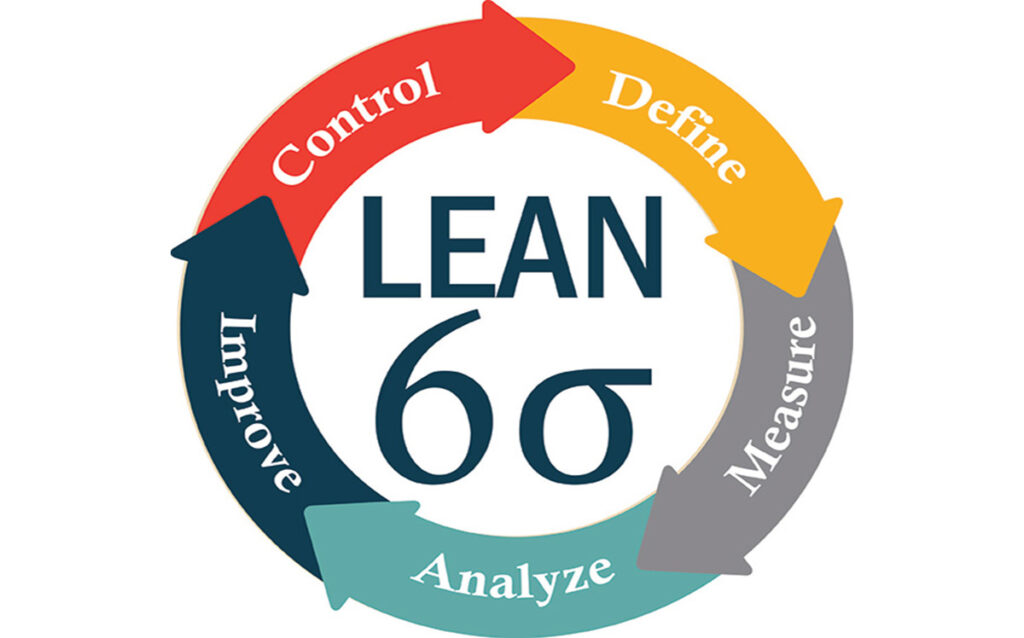

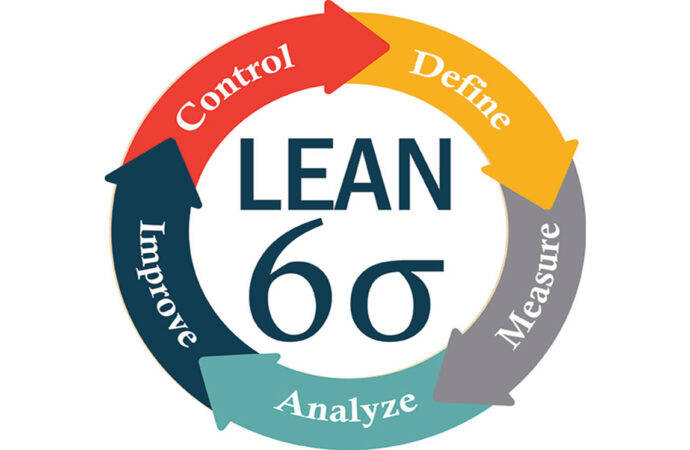

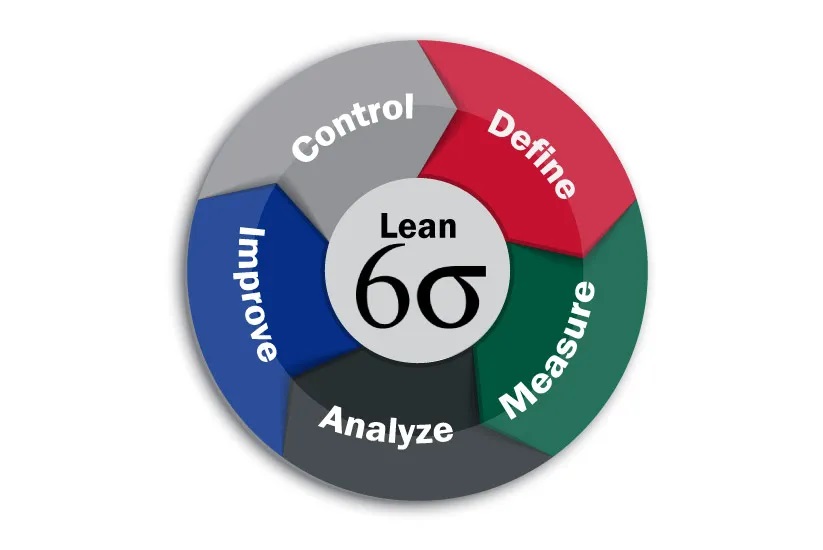

It is crucial to know that although LSS is an answer to the Japanese method and U.S. companies have started to follow most of its principles (if not all), the Lean Six Sigma methodology is actually a combination of two individual ones developed the main one previously.

This is why we need to learn about Lean and Six Sigma as two separate elements that came together.

The first one, Lean, is often introduced as “thinking” due to the structure and principles established around it.

To understand where it came from, people often use the term “Toyota” when referring to its origins.

Toyota refers to its system as the “Toyota Production System” (TPS). John Krafcik was a researcher during his time at MIT in 1987. He was searching for a label to describe the TPS system. He wrote down the characteristics of the Toyota system in comparison to traditional mass production on a whiteboard. After his research and analysis, he concluded: “To create a certain amount of value, the system requires less of everything.”

Lean Thinking grew quickly with a focus on reducing non-value-added activities or waste, and the Japanese influence comes as, in Japan, principles of Kaizen focus on reducing everything to get more results while also getting rid of Muda, which is how Japan call this type of waste mentioned by Krafcik, which is why Lean is also considered to come from Japan as clear principles and fundamentals are based from Kaizen.

Of course, Lean establishes its own principles and foundations, starting with understanding the customer, identifying and comprehending the value stream and waste for each process, value flow, customer value, and perfection based on a constant pursuit (this last one influenced by Kaizen or entirely based on it).

On the other hand, Six Sigma is a US-based organization that has roots back in the 1980s. Six Sigma can be traced back to Motorola. Motorola’s CEO Bob Galvin, then a struggling competitor to foreign manufacturers, set a goal for tenfold improvement within five years.

This plan was focused on global competitiveness, participative management, and quality improvement. Six Sigma was the standard for all Motorola business processes in no time, and all Motorola employees received training.

Strong leadership was the key to Six Sigma’s success as Welch, a G.E. “Neutron Jack,” was a well-known leader, although he had a different style than Toyota’s. The world learned from G.E. that Six Sigma is not just a quality program. It can be applied to all types of businesses, not just manufacturing.

In the end, when put together, both Six Sigma and Lean are based on the recognition that it’s the process that must be changed. Six Sigma greatly enhances the Lean approach.

Why Is Lean Six Sigma Used?

History gives us a clear idea of why LSS is used: to improve processes, productivity, efficiency, and reduce waste.

It is a good idea to have a clear concept of what Lean, Six Sigma, and Kaizen offer regarding principles and solutions, so the reasons and benefits behind LSS and its use are clearer.

In the case of Lean, it allows companies and workers to understand the customer and prioritize their needs while still focusing on the value stream, processes, and value flow of the company to achieve perfection without any waste.

Six Sigma pursues excellence and a structure that guarantees clean processes and more efficiency. Operational and business excellence is just the beginning, while continuous improvement and innovation are part of the main goals around 6 Sigma.

Finally, the Kaizen method has five elements to remember: teamwork, personal discipline, improved morale, quality circles, and suggestions for improvement. When analyzing it and considering Lean has its origins from this one, you can notice what they have in common, they aim for improvement and collaborative work.

Thus, Lean Six Sigma is used due to the benefits that it brings to any company and business but also any student and professional getting trained:

- Understand how to decrease waste.

- Increase efficiency.

- Reduce errors.

- Reduce the company’s legal risks.

- Improve time management.

- Reduce costs, allowing for higher revenues and salaries.

- Boost employee motivation.

- Leadership and innovation fundamentals.

How to Get Trained in Lean Six Sigma

Feel free to contact our team at Lean Six Sigma Curriculum Pros of San Antonio. Besides knowing everything about its history and how it works, we are qualified and experienced to teach any high school student, college student, business professional, or an entire company how to follow and implement LSS in their lives and processes.

We aim to ensure you get all the benefits and can be a relevant resource in any company or place you decide to work.

For companies, growth and innovation never looked easier than just having your employees and experts get certified in one of our belts.